PC Board

Cleaning and Preparation

In the manufacturing of printed circuit boards (PCBs), water is crucial for cleaning and preparing the copper-clad laminate. It effectively removes dust, oils, and contaminants, ensuring proper adhesion for etching and other chemical processes. CST can enhance this step by providing innovative solutions to generate water by condensing it from the atmosphere, ensuring a sustainable and efficient water supply for PCB manufacturing. This approach not only reduces reliance on external water sources but also supports eco-friendly practices in the industry.

Etching, Plating & Surface Finishing

In the PCB manufacturing process, water plays a vital role during the etching and plating stages. After applying a photoresist layer and exposing it to create the desired circuit pattern, water is used to rinse off the chemicals used in etching, effectively removing unwanted copper and forming the circuit pathways. Similarly, during the plating process, where metals like copper or gold are deposited onto the PCB, water rinses away excess chemicals and residues, ensuring a clean finish. CST's techniques for generating water from the air can significantly enhance this process by providing a sustainable water source, reducing dependence on traditional water supplies, and promoting eco-friendly practices in the PCB industry.

Drilling, Cutting Using Lubricants

In PCB manufacturing, water plays a vital role during the drilling and cutting processes, where it is used for cooling and lubrication at high speeds to prevent overheating and ensure clean holes for vias that connect different layers. Following assembly, water is also employed in the final cleaning phase to rinse off flux residues and other contaminants, ensuring the integrity and reliability of the boards. CST technologies can enhance this process by providing sustainable solutions for generating water from the atmosphere, ensuring a consistent and efficient supply for these critical manufacturing steps.

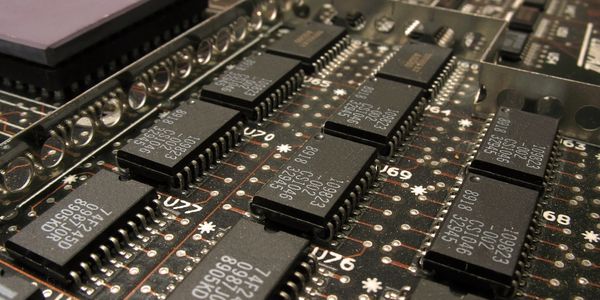

IC Chips & Semi Conductors

Water is crucial in the manufacturing process of IC chips, serving multiple roles such as cleaning silicon wafers, rinsing off chemicals after processes like photolithography and etching, and cooling equipment during high-temperature operations. Efficient cooling can be achieved using CST's Dry Coolers, Open Type Cooling Towers, Closed Loop Cooling Towers, or Adiabatic Cooling Towers to manage temperatures effectively. Additionally, where water is consumed in the manufacturing process, it can be sourced sustainably through technologies that condense water from the air, reducing reliance on traditional water sources and promoting eco-friendly practices in semiconductor manufacturing.

Copyright © 2026 Enviro Breeze - All Rights Reserved.

Powered by GoDaddy