Water Substituting

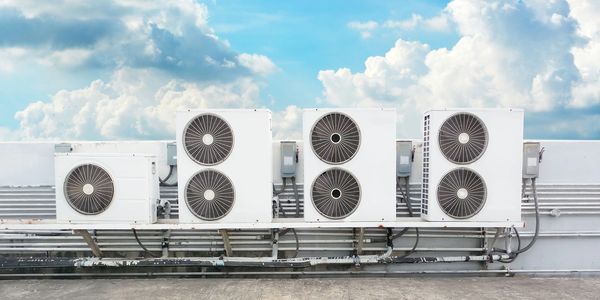

Air Cooled Gas Coolers

With water shortages impacting industries that previously relied on water-to-gas / air heat exchangers, we can now replace liquid coolers with air-to-gas systems. A typical example is the Charge Air Cooler (CAC) in DG sets and Endo Gas Generators, where gas exits the generator at 1000°C and needs to be cooled to 100°C. The CST team can help solve this problem with effective air-to-gas heat exchangers.

Air Cooled Oil Cooling

In processes where oil exits machinery or production lines, companies typically use air-to-water heat exchangers for cooling. However, these can be effectively replaced with air-to-oil coolers, which offer long-term reliability. CST air-cooled oil coolers are designed to operate efficiently for years with minimal maintenance.

Steam Condensing

In processes where steam needs to be condensed, companies often rely on traditional cooling methods. However, these can be effectively replaced with air-to-steam condensers. CST air-cooled steam condensers or Dump Condensers are designed for long-term reliability, providing efficient performance for years with minimal maintenance.

Copyright © 2026 Enviro Breeze - All Rights Reserved.

Powered by GoDaddy